Trece. desollar

Hay dos fenómenos comunes de la piel: uno está en el cubo de embalaje de la piel de la superficie del pegamento, el otro está en la piel de la superficie de la bandeja del pegamento.

■ La capa superficial de pegamento en el balde de empaque produce costras

1) Si la temperatura del empaque de filtración de pegamento es demasiado alta, es fácil formar una costra en el barril cuando baja la temperatura, lo cual es común en verano a altas temperaturas. Debido a que el pegamento se enfría lentamente, es fácil que ocurra si los productos son urgentes y no se pueden empacar a la temperatura adecuada.

2) El pegamento empaquetado también formará una costra si se expone a la luz solar.

■ Produce costras en la capa superficial de cola de la bandeja de cola

1) La bandeja de pegamento tiene un ángulo muerto (como la forma de ángulo recto de la bandeja de pegamento) cuando el pegamento rara vez fluye, la superficie de la humedad del pegamento se volatilizará lentamente, formando una película y una costra.

2) El camino de cocción tiene aire caliente que sopla directamente a la bandeja de pegamento.

3) La superficie de más espuma de espuma adhesiva es muy delgada, fácil de filmar.

Catorce. Espuma

La espuma también se divide en espuma de cubo y espuma de pegamento en dos casos

■ Espuma en el barril

Esta situación se debe principalmente a la violenta agitación en el proceso de manipulación de la espuma, además de que la infiltración de más agua agitando también producirá más espuma.

■ Salida lenta de la bandeja de pegamento cuando hay espuma más seria

1) Fallo del antiespumante de cola o medición insuficiente

2) la velocidad de las cunas superiores es demasiado alta y la mezcla del pegamento es demasiado fuerte

3)The level of the rubber layer and the upper cots are in an inappropriate position, and a large amount of gas is brought into the upper cots when they rotate.

4)The glue viscosity is too high, and the glue foam wall is thick and not easy to burst.

■ More glue foam, the consequences are as follows:

1)Influence the speed of composite (laminating speed)

2)When the amount of glue is large, part of the foam is coated with the film, and the foam enters the baking channel before leveling after bursting, or enters the baking channel before bursting, and then dries and breaks to form empty points. After composite, the phenomenon like fisheye and pinhole is generated.

3)It is easy to produce glue crusts in the glue tray.

In the way of dealing with more foam, the common way is to add defoaming agent, but we must pay attention to the type, quantity and stirring method of adding defoaming agent. If the operation is improper, it is easy to cause the phenomenon of fisheye and peeling force decline.

Fifteen. paperhanging

Simply speaking, pasting is the paper and paper bonded together, so that it has better strength and stiffness, such as cardboard boxes, corrugated boxes. The same kind of paper is called to mount, and there are all kinds of common hanging tags.

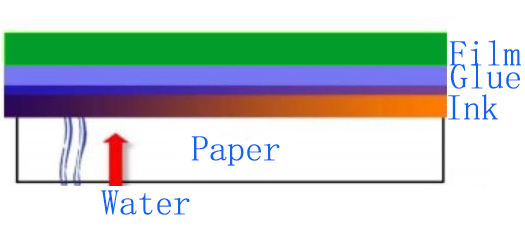

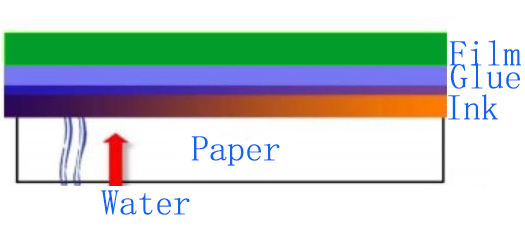

At present, most pasting adhesives used for pasting have low solid content and contain more moisture. Because of the structure of the paper, there are a lot of capillary tubes in it.

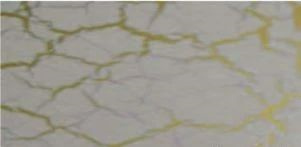

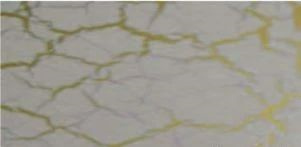

After pasting, due to capillary action, moisture is quickly absorbed by the paper and rises to the glue layer, affecting the glue layer and surface layer.In a short time, it is difficult to volatilize water completely, especially in winter, and the adhesive layer contact for a long time. Due to the hydrophilic characteristics of water-based adhesive, the existence of water will certainly destroy its structure, resulting in a decline in performance.Its main performance is the decline of adhesion, peeling film and adhesive layer is separated, in addition, if the water is not completely volatile that the next process such as die cutting, indentation and so on, easy to cause foaming phenomenon.

This requires that the moisture content of the paper itself should be low. After the composite pasting, the products should be placed for a long time and in a dry and warm environment as far as possible, so as to volatilize the water and reduce the influence of water on the adhesive layer.

Sixteen. drying speed

The drying speed of glue directly affects the speed and efficiency of laminating, and is also an important aspect for customers. The main factors that affect the drying speed are: the temperature of the drying channel and the ventilation volume, the solid content of the glue, the solvent structure of the glue.

■ Temperature and ventilation of the drying channel

The requirements of the drying road will be paid attention to, but ventilation can not be ignored, if there is a large number of steam in the drying road can not be excluded, it will greatly affect the speed of drying, and often there will be water droplets, dripping on the film, causing coating problems, in addition to the equipment also has the effect of corrosion.

■ Solid content of glue

In general, glue with a higher solid content dries faster

■ Solvent structure of glue

Glue containing organic solvents and water miscible drying speed is relatively fast, so it is necessary to remind customers of some faster drying glue to pay attention to its environmental problems.

It should be noted that, in the case of large amount of glue, can not be too pursuit of drying speed, if only by increasing the drying temperature to improve the drying speed, often cause the surface dry and the inner layer is not dry phenomenon, so that not only affect the film performance, serious cracking phenomenon.

Seventeen.odor

There are three kinds of odor problems in glue: ammonia smell, single body odor, bad smell.

■ Ammonia smell

The PH problem was mentioned earlier, and the common regulator of PH is ammonia. Ammonia has a certain volatile and pungent smell. Under the condition of normal glue, ammonia generally has a light taste, while if ammonia has a heavy taste, it is related to the following situations:

1)In order to increase the viscosity of the glue, excessive ammonia was added.

2)The compound environment was not well ventilated, resulting in the accumulation of volatilized ammonia.

3)After the summer sun exposure, some ammonia volatilized into the space of the glue bucket, and the ammonia smell was heavier when the lid was opened.

■ Single body odour

Si el monómero tiene un sabor fuerte, el pegamento no es completamente reactivo o el monómero residual es alto.

■ Mal olor

Debido a que el solvente del pegamento es el agua, y el agua es el espacio para la supervivencia de los microorganismos, por lo que la producción general de pegamento debe ser un tratamiento de esterilización, si el tratamiento no es bueno, después de un período de tiempo, puede haber un gran número de microorganismos causados por el deterioro del pegamento, olor.

Adhesivo en el proceso de uso, si se mezcla sin tratamiento de esterilización de agua, también es fácil causar deterioro.

español

español English

English français

français русский

русский العربية

العربية