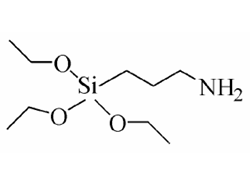

(1)KH-550 agente de acoplamiento de silano

â Alias: 3 trietoxisililpropilamina; AMEO

CAS: 919-30-2

Líquido transparente incoloro o amarillo muy pálido. Es soluble en disolventes orgánicos, pero la acetona y el tetracloruro de carbono no son adecuados como diluyentes. Es soluble en agua y se hidroliza en agua. El silano aminofuncional es básico, tiene alta reactividad y es muy versátil. La porción de silicio de la molécula puede proporcionar una unión fuerte al sustrato. El grupo funcional amina principal puede reaccionar con una variedad de resinas termoendurecibles, plásticos termoplásticos y materiales de caucho sintético.

â¡Fórmula química o fórmula molecular y fórmula estructural: C9H23NO3Si; NH2CH2CH2CH2Si (OC2H5) 3. Fórmula estructural:

â¢Propiedades físicas y químicas e indicadores de calidad

Punto de fusión: -70°C

Punto de ebullición: 217°C

Punto de inflamación: 104°C

Densidad: 0,946 g/cm3

Índice de refracción: 1,4205

Contenido: â¥97%

Aplicación principal

Se utiliza principalmente en los siguientes aspectos.

a.Refuerzo de fibra de vidrio

puede mejorar en gran medida la resistencia a la flexión, la resistencia a la tracción y la resistencia al corte interlaminar en condiciones húmedas y secas, y mejorar significativamente el rendimiento eléctrico húmedo. Cuando este agente de acoplamiento de silano se utiliza tanto en condiciones secas como húmedas, la resistencia a la flexión y a la tracción de los termoplásticos, poliamidas, poliésteres y policarbonatos reforzados con fibra de vidrio aumenta antes y después de la inmersión en agua.

b.Adhesivos y selladores

Es un excelente acelerador de adhesión, que puede mejorar la dispersión de pigmentos y aumentar la adhesión al vidrio, aluminio y acero.

c.Materiales aislantes minerales y de fibra de vidrio

Agregar adhesivo de resina fenólica puede mejorar la resistencia a la humedad y la resiliencia después de la compresión

d.Rellenos minerales y sistemas de resinas

Puede mejorar en gran medida las propiedades físicas, mecánicas y eléctricas de resinas termoplásticas y termoendurecibles como resina fenólica, resina de poliéster, epoxi, poliuretano y policarbonato rellenos con cargas inorgánicas, y mejorar la humectabilidad y dispersión de cargas en polímeros.

e.Aplicaciones de fundición

Puede mejorar la adhesión del adhesivo fenólico y la arena de fundición. Es útil para mejorar la adherencia y la resistencia al agua de la arena autoendurecible y el adhesivo fenólico resistente al desgaste.

f.Tratamiento de superficies metálicas

Después del pretratamiento de la superficie de aluminio con una solución de etanol KH-550 al 5 %, la resistencia al corte por tracción de la unión aluminio-aluminio con adhesivo epoxi se puede aumentar en un 19,5 %. La solución KH-550 se une químicamente al sustrato de aluminio después del recubrimiento, en lugar de simplemente una adsorción física. Obviamente, puede mejorar la fuerza de unión del aluminio y la interfaz de unión adhesiva.

g.Adhesivo de neopreno injertado

Se utilizó un agente de acoplamiento de silano γ-aminopropil trietoxisilano (KH-550) para mejorar las propiedades del adhesivo de neopreno injertado. A medida que aumentó la proporción de KH-550 a neopreno injertado, aumentó el contenido de sólidos. Entre ellos, cuando la concentración es del 2% al 5%, la adherencia es mejor. Además, se utilizó el complejo casero de hexametilentetramina-isofenol para preparar adhesivos FM con KH-550 y otros aditivos, que tiene buena adhesión a los metales, resuelve el problema de la mala adhesión de los adhesivos de silano a los metales y mejora la adhesión de la solución adhesiva original de FM. . Se disolvieron KH-550 y titanato de tetrabutilo en etanol en una determinada proporción y se preparó un nuevo agente de acoplamiento mediante calentamiento, agitación y reflujo, que se utilizó como agente reticulante para caucho de silicona vulcanizado RT de dos componentes. En el enlace con aluminio, los átomos de titanio y los átomos de aluminio podrían formar enlaces de coordinación, y los átomos de amino podrían proporcionar átomos de hidrógeno para formar enlaces de hidrógeno, lo que podría mejorar en gran medida la fuerza del enlace. Al mismo tiempo, el agente de acoplamiento también puede desempeñar un papel en la promoción del curado. También se puede utilizar para modificar adhesivos de emulsión de poliuretano a base de agua, que tienen excelentes propiedades de adhesión, resistencia al agua y mecánicas.

â£Protección del medio ambiente

Puede causar quemaduras.

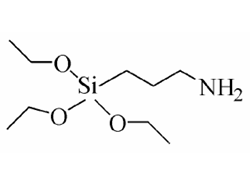

(2)Agente de acoplamiento de silano KH-551

â Nombre y carácter

Alias: 3 (trimetoxisilil) -1-propanamina; KBE 903.

CAS: 13822-56-5.

Líquido transparente incoloro

â¡Fórmula química o fórmula molecular y fórmula estructural: C6H17NO3Si. Fórmula estructural:

â¢Propiedades físicas y químicas e indicadores de calidad

Punto de fusión: <-60°C. Punto de ebullición: 91 ~ 92 ℃. Densidad: (0,9160±0,0005) g/cm3. Índice de refracción: 1,4270 ± 0,0005.

⣠Uso principal

Se puede utilizar en los siguientes aspectos.

a.Los grupos amino y etoxi se utilizan para acoplar polímeros orgánicos y cargas inorgánicas, respectivamente, para mejorar sus propiedades de unión, mejorar la resistencia mecánica, eléctrica, al agua, al envejecimiento y otras propiedades del producto. Es adecuado para resinas termoplásticas y termoendurecibles con carga mineral, como aldehído fenólico, poliéster, epoxi, PBT, poliamida, carbonato, etc., que pueden mejorar en gran medida las propiedades físicas y mecánicas de resistencia a la flexión en seco y húmedo, resistencia a la compresión, resistencia al corte y propiedades eléctricas húmedas de plásticos reforzados y mejorar la humectabilidad y dispersión de cargas en polímeros. En la fundición de arena de sílice de resina, se mejora la adhesión de la arena de sílice de resina y se mejora la resistencia a la humedad y la resistencia a la humedad de la arena de moldeo. En la producción de fibra de vidrio, algodón y lana mineral, se puede agregar a adhesivos fenólicos para mejorar la resistencia a la humedad y la resiliencia a la compresión.

b.Excelente acelerador de unión para poliuretano, epoxi, nitrilo, adhesivos fenólicos y materiales de sellado para mejorar la dispersión de pigmentos y aumentar la adhesión a vidrio, aluminio, metales de hierro, también adecuado para revestimientos de poliuretano, epoxi y látex acrílico.

c.Utilizado para sellar poliuretano a base de agua modificado, cuando la cantidad de KH-551 es del 4% al 5%, el adhesivo de poliuretano al agua modificado tiene buenas propiedades mecánicas, resistencia al agua y resistencia a los solventes. También se utiliza en la síntesis de aceite de aminosilicona y su emulsión.

⤠Seguridad ambiental

Provoca quemaduras e irritación en los ojos y la piel.

(3)Agente de acoplamiento de silano KH-560

Alias: 3 glicidiloxipropiltrimetoxisilano

CAS: 2530-83-8. Cuerpo líquido transparente incoloro

Se disuelve en agua y al mismo tiempo se produce una reacción de hidrólisis que libera metanol. Soluble en alcohol, acetona y la mayoría de los ésteres alifáticos en niveles de uso normal inferiores al 5%. Este producto es un agente de acoplamiento de silano funcional epoxi.

â¡Fórmula química o fórmula molecular y fórmula estructural: C9H20O5Si. Fórmula estructural:

â¢Propiedades físicas y químicase indicadores de calidad

Punto de fusión: <-70°C

Punto de ebullición: 119 ~ 121ºC (266,64Pa)

Punto de inflamación: 135°C

Densidad relativa: 1,065 ~ 1,072

Índice de refracción: 1,428 ~ 1,43.

Aplicaciones principales:Ampliamente utilizado en adhesivos como resina epoxi, resina fenólica, acrilato, poliuretano, resina de melamina-formaldehído y resina de poliéster insaturado. Este producto puede mejorar la adhesión entre la resina y el sustrato, mejorando así las propiedades eléctricas de los materiales electrónicos y los envases fabricados con resina epoxi. Cuando se emplea en adhesivos, selladores y rellenos epoxi, polisulfuro, uretano y acrílico, puede mejorar la adhesión a sustratos de vidrio y metal. En un sistema de curado de un sellador de polisulfuro a base de resina epoxi, puede mejorar significativamente la adhesión y el efecto de sellado. Utilizado como acelerador de unión, cuando el silano KH-560 se trata sobre la superficie de una aleación de aluminio en una solución acuosa débilmente ácida (metanol, agua, ácido acético glacial, pH = 5), los grupos silanol exhiben la adsorción más óptima en el aluminio. superficie de aleación al 2%. Cuando se utilizan adhesivos epoxi, se forma un enlace covalente, lo que mejora significativamente la durabilidad de la unión. Cuando se agrega un 5% del agente de acoplamiento KH-560 a los adhesivos fenólicos-nitrilo, puede absorber la humedad en el adhesivo y en la interfaz de unión, mejorando el rendimiento del procesamiento, aumentando la fuerza de la unión y mejorando la resistencia al envejecimiento. Cuando el agente de acoplamiento de silano KH-560 se usa como modificador para bigotes de carbonato de calcio, los bigotes de carbonato de calcio modificados por KH-560 se emplean en adhesivos de aislado de proteína de soja (SPI). Cuando la dosis de KH-560 es del 4% (fracción de masa), la dosis de bigotes de carbonato de calcio es del 2% (fracción de masa) y el contenido de SPI es del 10% (fracción de masa), el rendimiento de unión y la resistencia al agua del sistema son óptimos. En comparación con el adhesivo SPI sin modificar, la resistencia al corte en seco aumenta en un 28,88%, la resistencia al corte post-inmersión aumenta en un 71,41% y la resistencia al corte en húmedo aumenta en un 76,68%. La temperatura de distorsión por calor es más baja que la del adhesivo SPI no modificado.

⤠Seguridad ambiental

Nocivo en contacto con la piel. Irrita los ojos y la piel.

Más, como: KH-580, KH-590, KH-602, KH-792, etc., SinograceChemical también tiene, bienvenido a consultar.

español

español English

English français

français русский

русский العربية

العربية